Our Services

We have on board 15 years’ experience Senior Welding inspectors AWS qualified and CSWIP 3.1 available for site work and workshop based anywhere in Australia.

- NDT services provided

- Magnetic particle inspection

- Dye penetrant inspection

- Ultrasonic weld examination

- Ultrasonic thickness survey and lamination check

- UTEA-Ultrasonic end areas on drill pipe

- EMI buggy logging- Drill pipe range 2 3/8″ to 5 1/2″ category 1- 5 inspection

- Field refacing on connections

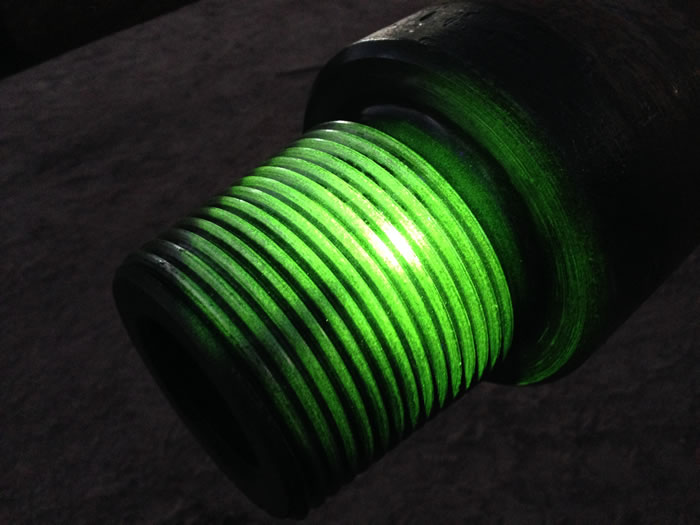

- Visual inspection on API Threads

- Visual inspection on new welds.

Other Services We Provide:

- Eddy current inspection on cranes, siccorlift boom and any structural welds

- Material Hardness Testing

- Positive Material Identification

- Radiography on Pipes

Our business is designed to provide Australian standard non destructive testing options for drill pipe testing and metal manufacturers in Toowoomba and the Surat Basin areas.

Magnetic Particle Inspection (MPI) is an inspection method used to find surface breaking and near sub-surface flaws in ferrous materials.

Dye Penetrant Inspection (DPI) used to locate surface breaking defects in non-porous solid materials such as metals, composites, plastics and ceramics.

Ultrasonic Testing (UT) is an inspection method that uses sound waves to detect internal flaws, measure thicknesses and monitor corrosion in a variety of materials.

Visual Testing (VT) is a versatile inspection method used to evaluate the condition or quality of an weld.

Ultrasonic gauging checks are generally used to determine material thicknesses when detecting hidden laminations.

Our business is designed to provide Australian standard non destructive testing options for drill pipe testing and metal manufacturers in Toowoomba and the Surat Basin areas.

Services

We have on board 15 years’ experience Senior Welding inspectors AWS qualified and CSWIP 3.1 available for site work and workshop based anywhere in Australia.

- NDT services provided

- Magnetic particle inspection

- Dye penetrant inspection

- Ultrasonic weld examination

- Ultrasonic thickness survey and lamination check

- UTEA-Ultrasonic end areas on drill pipe

- EMI buggy logging- Drill pipe range 2 3/8″ to 5 1/2″ category 1- 5 inspection

- Field refacing on connections

- Visual inspection on API Threads

- Visual inspection on new welds

Services

Other Services We Provide

Our business is designed to provide Australian standard non destructive testing options for drill pipe testing and metal manufacturers in Toowoomba and the Surat Basin areas.

- Eddy current inspection on cranes, siccorlift boom and any structural welds

- Material Hardness Testing

- Positive Material Identification

- Radiography on Pipes

Image box with left border

Insert and customize your Elementor Image box with the left border and display it to your wordpress sites.

Magnetic Particle Inspection

Magnetic Particle Inspection (MPI) is an inspection method used to find surface breaking and near sub-surface flaws in ferrous materials.

Ultrasonic Testing

It is an inspection method that uses sound waves to detect internal flaws, measure thicknesses and monitor corrosion in a variety of materials.

Ultrasonic Gauging testing

Do you know how to add image box in WordPress website with elementary. Download Elementskit.

Dye Penetrant Inspection

Dye Penetrant Inspection (DPI) used to locate surface breaking defects in non-porous solid materials such as metals, composites, plastics and ceramics.

Visual Inspection

Visual Testing (VT) is a versatile inspection method used to evaluate the condition or quality of an weld.

Drill Pipe Testing

Our business is designed to provide Australian standard non destructive testing options for drill pipe testing and metal manufacturers in Toowoomba and the Surat Basin areas.