Ultrasonic Testing

Ultrasonic Testing (UT) is an inspection method that uses sound waves to detect internal flaws, measure thicknesses and monitor corrosion in a variety of materials.

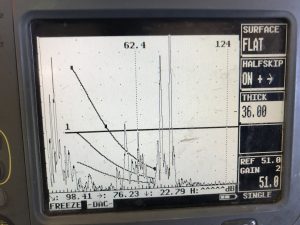

UT involves the transmission and capture of pulsed beams of high frequency ultrasound. A hand held transducer (probe) is placed on the specimen. Flaws anywhere through the specimen reflect the sound back to the probe. The ultrasound reflection is displayed on portable equipment which is calibrated to feedback the flaw size, distance (location) and reflectivity.

Advantages of UT include the detection of flaws, corrosion and thicknesses on ferrous and non-ferrous materials, and composites.

It is a versatile method and can be adapted to suit inspection of single components, batch production or mass production by the use of hand held or automated systems.