Dye Penetrant Inspection

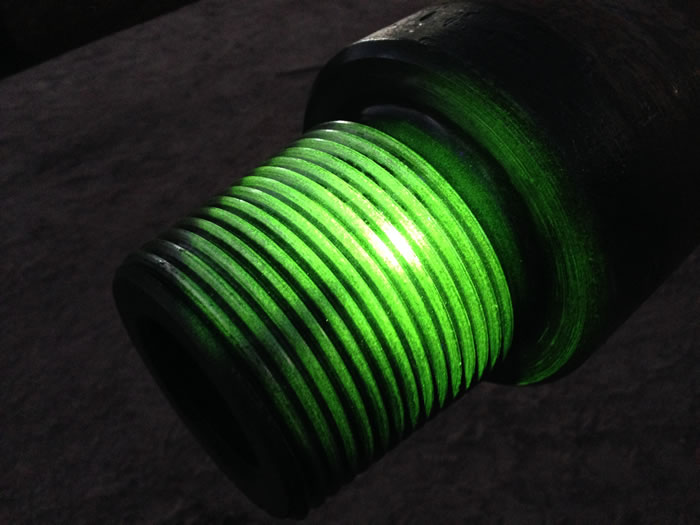

Dye Penetrant Inspection (DPI) used to locate surface breaking defects in non-porous solid materials such as metals, composites, plastics and ceramics.

Penetrant inspection uses capillary action to draw the dye into the flaw. A developer is then applied to draw the penetrant from the flaw and reveal its presence on the surface. Inspection is performed using white light for colour contrasting penetrants and ultraviolet light for penetrants.

Advantages of the penetrant method include low cost, in service component testing and its ability to be combined with other methods such as magnetic-particle inspection or ultrasonic inspection, to detect the subsurface defects in ferrous materials. Include detecting leaks, defects, cracks and fatigue on casting, forging, new and in service and in-service components